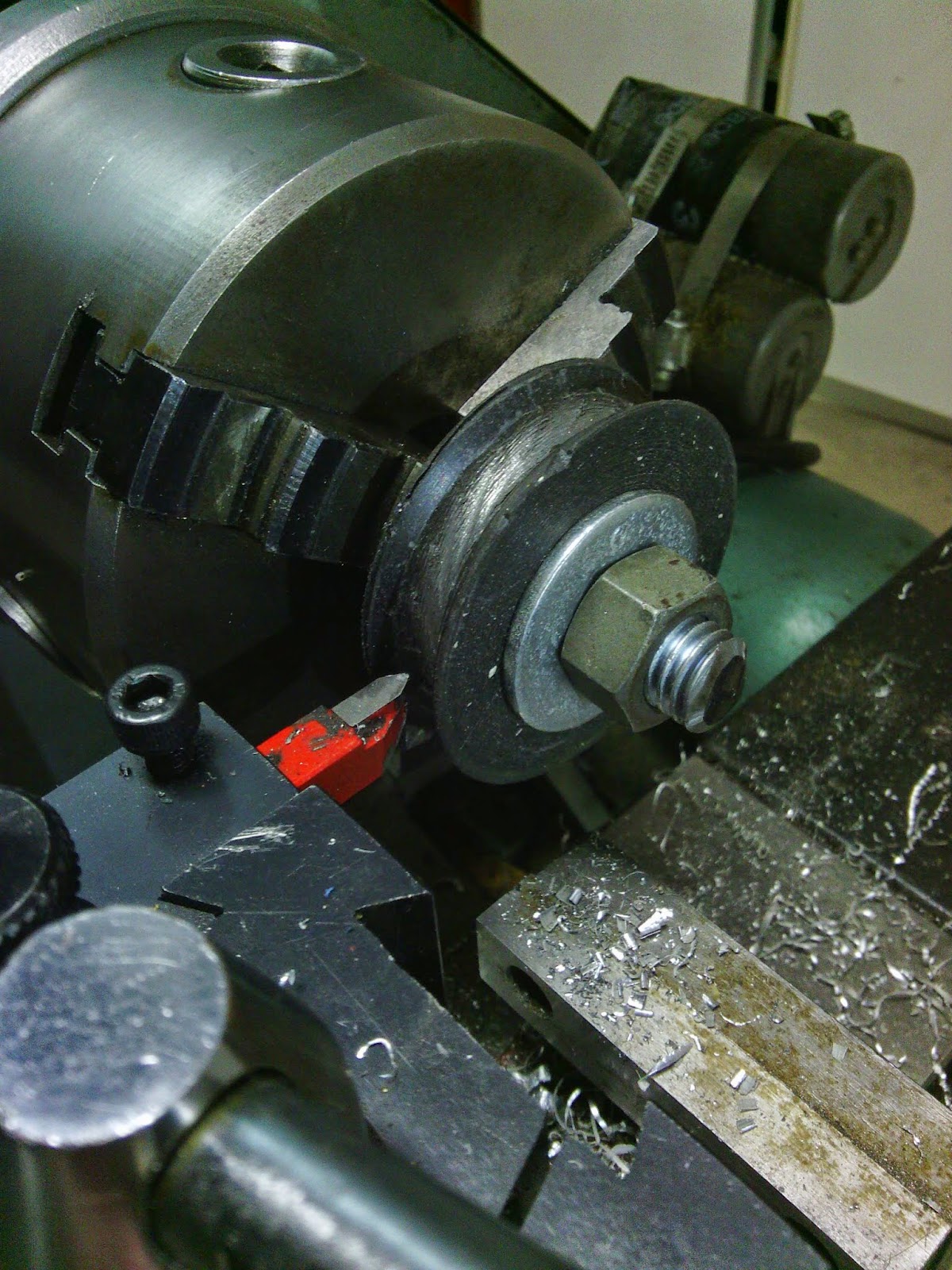

So this is how my mind works when I am not in school or working. Parker and I were playing with an old box of Legos and Construx when I saw a little Construx pulley that reminded me of the spaceship zip lines I would make with string off my parent's balcony when I was younger. My first thought was to make something similar for Parker to play with. Then I thought why play with Legos when I could put parker on it. Then I was reminded of the last add I had seen from Harbor Freight and how cheap you can get 1/4 inch steel cable. Within a few hours I had Parker flying across our lawn... I like to think that Parker has enjoyed having me around more the last few months. One problem I ran into is that most pulleys use aluminum sheaves (the wheel of the pulley). Because the steel cable is a harder material, every time someone would go down the zip line on the original pulley they would get little bits of aluminum raining down on them. I decided to make my own trolley. I started by using the lathe to shape plastic from a cutting board for the sheaves and using ball bearings from an old set of rollerblades.

I then cut out a basic housing for new trolley.

It took Parker a couple days to warm to it but he was really hooked once I added the seat.

Here is a video of Parker in action.